Development of conformal electrode arrays for surface recordings of the enteric nervous system

Irritable bowel syndrome (IBS) is the most common functional gastrointestinal (GI) disorder worldwide. It is estimated that 10–15% of the population is affected by IBS. IBS and other GI disorders, such as inflammatory bowel disease (IBD) which includes ulcerative colitis and Crohn’s disease, are diseases that are related to a dysfunction of the enteric nervous system (ENS). Understanding how the dysfunction of enteric nerves is related to GI disorders could help to improve the lives of millions of people. What if we were able to develop a gut pacemaker to actively regulate and stimulate impaired bowel activity?

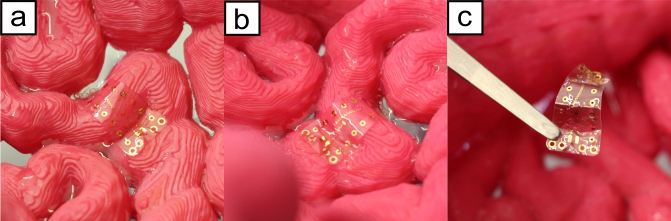

Although the ENS has the largest population of neurons in the peripheral nervous system, it is not well understood and is less investigated than the central nervous system. Most of the information gathered about the function and electrophysiology of the ENS was performed ex vivo, either on pathological samples or in cell cultures. Common methods include patch clamp recordings on explanted tissue and imaging tissue in vivo, or in vitro. Current strategies for in vivo recording and stimulation of the gut are limited by lack of conformation to complex surface topography and flexibility for tissue movement. Thus, conventional stiff or cuff type electrodes cannot conform to the gut surface, do not achieve strong electrical coupling, and are susceptible to motion artifacts since they will be moving relative to the bowel.

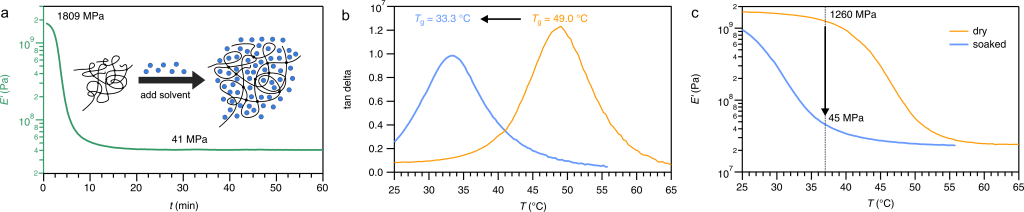

We propose that the problems caused by conventional, stiff electrodes can be solved with the use of an electrode substrate that is of a self-softening polymer. The hypothesis is that the polymer is capable of softening and changing its shape so that the device can adapt to the shape and surface topology of its surroundings. It will wrap tightly around the gut, securing the electrodes in place to enable continuous periodic recordings of motor and sensory neurons from the myenteric and submucosal plexus.

With this proposed research, we hope to learn more about the ENS and its correlation to GI disorders.

Development of highly stretchable electrode arrays

For multiple in vivo applications, it would be beneficial if the electrode arrays would not only be flexible and conformal but also highly stretchable in order to withstand tissue and body movements without tearing. In particular, spinal cord stimulators and peripheral cuff and blanket-like devices may undergo considerable deformation during chronic applications. To fabricate fully elastic electronic devices it is not only important to have an elastic substrate, but also to have stretchable electronics. The first aspect, the substrate material, can easily be solved by the use of elastomeric polymers such as rubbery silicone. However, the materials that are commonly used for the electrodes, and the traces are metals such as gold, titanium nitride, or platinum, and these materials are stiff and not stretchable. Often, the traces are shaped like serpentines in order to achieve some stress relief in the direction of tension, but this does not prevent the traces from breaking if too much strain is applied.

We are aiming to develop highly stretchable electrode arrays for surface recordings and stimulations (e.g. cuff electrodes and spinal cord stimulators) using elastic polymers as substrate material with conductive polymer composites (CPCs) as the electrode and trace material. The conductive characteristics of the polymer matrix can be changed through the incorporation of a filler into the polymer matrix. Different conductive filler materials, such as PEDOT, carbon nanotubes, and graphene will be investigated.

Currently, we are building a custom 3D printer that will enable us to directly print conductive traces on our polymeric substrates to create highly stretchable electrode arrays.